Warehouse Traffic Management Systems

In any industry, a warehouse is a vibrant place that hosts a variety of activities taking place day in and out. Pedestrian workers, moving vehicles and forklifts, loading and unloading of cargo can all lead to unpleasant situations, accidents, injuries, even death. Hence, it is of vital importance that a proper warehouse traffic management safety system is in place that ensures the safety and wellbeing of the workers.

In a typical warehouse, with only a few exceptions, the following activities take place at any given time:

- Goods are received and unloaded from the vehicles

- These goods are then transferred onto pallets for storage

- Transferring the storage containers to their locations

- Sorting the orders received and dispatching the goods to the customers

All these activities necessitate movement of people, material, and machinery from one location to another. No matter how coordinated, planned, or organised these activities may be, there are bound to be lapses resulting in mishaps if there is no warehouse traffic management system in place.

Essentials of a Warehouse Traffic Management System

Every organisation must study the design and layout of their warehouse/s and accordingly devise a plan with the help of safety and security experts. There are a few basic but key rules to keep in mind:

- In order to ensure the protection and safety of the pedestrians, eliminate traffic hazards. It is easily achieved by identifying areas where there is a greater chance of interaction between pedestrians and vehicles.

- Regulate the operation and routes the vehicles take to load and unload the material.

- Designate the travel path of both the pedestrians as well as vehicles so that their paths do not cross or such instances are minimised.

- Install barriers, design walkways, install signs to warn and guide traffic around, past, or through the workplace.

- Conducting mock drills at regular intervals to ensure that the traffic management system is working to the plan and to identify loopholes, if any.

- The workforce should be made aware of the traffic management system, they should be able to understand its relevance and execution, receive information, instructions, and training at regular intervals.

How To Develop An Effective Warehouse Traffic Management System

Drafting and implementing an effective warehouse traffic management system isn’t a day’s or week’s job. It is a result of years of study, review, and experience of working with people and processes in busy warehouses and factories. When such a system is developed, it leads to not just safer workplaces but also efficient and productive ones. Let us take a look at some of the hallmarks of an effective warehouse traffic management system.

Designated Vehicle Routes

The vehicles in a warehouse are constantly on the move. They stop, unload goods, reverse, and so on. To deal with them, it is best to keep their lanes one-way. There should be separate entry and exit points for them, especially bigger vehicles. These routes should be free of oil, potholes, and preferably done in concrete so that there is proper grip for the tyres of the vehicles. To the extent possible, the vehicles routes should not have steep gradients but simple plain surfaces.

Pedestrian Zones

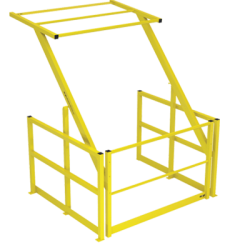

Pedestrians are the most vulnerable in a warehouse and so their zones should be clearly demarcated. Vehicles should not be allowed near these zones. Install barriers as needed to remind the pedestrians of entrances and exits. If the intersection of pedestrians and vehicles cannot be avoided, then warning lights and signs should be extensively used to mark such areas.

Signs and Instructions

The importance of signage and clear instructions can hardly be emphasised. All workers, drivers, and pedestrians must follow them to the core. The signs must be clearly legible, have bright backgrounds (attention grabbing), and be installed at a level higher than the eyes.

Some of the more common signs and instructions for warehouses are:

- Parking/No Parking Zones

- Speed Limits

- Restricted Areas

- Pedestrian Crossing

- Vehicle Crossing and Vehicle Parking

- Blind Corners

Forklift Safety

Forklifts are industrial lifting trucks that lift, stack, and transfer containers from one place to another. Forklifts are an integral part of warehouse operations. They are big machines and hence deserve a separate safety policy. More people are hurt or fatally injured in forklift accidents than any other mishaps in warehouses.

Dangers Associated with Forklifts

Forklifts are compact machines that do a great job with lifting stuff. However, when they are laden, they can become highly unstable and cause injuries to both the driver as well as workers in its vicinity.

- Instability: Forklifts are by nature unstable as they are designed to be extremely maneuverable. Due to this, they can tip over sideways or pitch over.

- Restricted Braking: Forklifts cannot apply sudden brakes as it may lead to sliding of the load or it may fall. So it is extremely dangerous to stand in front of a moving forklift.

- Reduced Visibility: Forklift drivers may face reduced visibility when the machines are fully loaded. Usually, the loaded stacks on a forklift get in the way of a good clear view for the driver.

Ensuring Forklifts Safety At The Warehouse

- The path or driveway of the forklifts should almost always be separate from pedestrians to the extent possible. The drivers should be aware of such zones where the forklifts cannot enter.

- Prescribe maximum load that a forklift can carry safely from point A to B without any chance of tipping over.

- The drivers or designated inspectors must check the forklifts regularly for any operational issues and take steps to rectify them when identified.

- The drivers must be trained and advised to strictly observe speed limits, follow warning signs, and wear proper uniform before operating the vehicle.

- After the end of the workshift, park the forklifts at their designated parking slots only.

Training and Supervision

No traffic safety mechanism or system can succeed unless the people whose safety it is meant for, understand it and abide by it. Every worker who enters your warehouse should understand the warehouse traffic management system.

They should be aware of designated pathways; for pedestrians as well as vehicles. They should know the speed limits in force and abide by them. Regular mock drills should be conducted and supervisors must ensure that the teams are correctly following the procedures.

Finally, every system should be flexible enough to adapt itself to changing work environment. Regular reviews should be conducted and possible loopholes identified so that corrective measures are enforced and systems are updated to reflect the changes. A rigid traffic management system will fail to cope up with the change in technology, products, and staff experiences and hence become ineffective in dealing with the day to day issues of warehouse safety.